How much does a plastic to oil machine cost ?

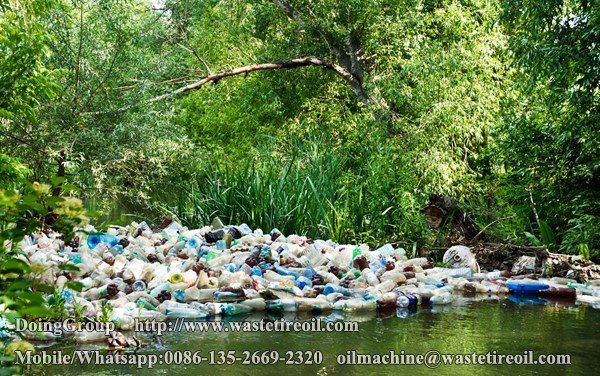

More and more people have discovered the business opportunity in waste recycling field. When you decide to start a plastic to oil machine to make money and relieve energy crisis, you should take the plastic to oil machine cost into consideration first. As a professional manufacturer of waste processing plant, DOING group has summarized these main factors which affects the plastic to oil machine cost. plastic to oil machine is a kind of machinery that can convert waste plastic /tyre to fuel oil ,carbon black and steel wire by advance pyrolysis technology. Price is the main factor affecting the plastic to oil machine cost.

As a professional manufacturer of waste processing plant, DOING group has summarized these main factors which affects the plastic to oil machine cost. plastic to oil machine is a kind of machinery that can convert waste plastic /tyre to fuel oil ,carbon black and steel wire by advance pyrolysis technology. Price is the main factor affecting the plastic to oil machine cost.

You know different capacity have different cost ,different design have different cost.You can choose the capacity and operating system according to your budget.

1.Raw materials cost

Utilizing waste plastics as raw material makes the plastic to oil machines have great profit margins. First of all, waste plastic is cheap in the market. Then, the plant can convert waste plastic into fuel oil and carbon black. Both of them are useful resources and have wide applications. Moreover, you can also use waste plastics, rubber, oil sludge, medical waste as raw material, which are all quite cheap in the market. With high value and stable prices in the market, these end-products will surely get your cost of raw materials back soon and bring great benefits for you.

First of all, waste plastic is cheap in the market. Then, the plant can convert waste plastic into fuel oil and carbon black. Both of them are useful resources and have wide applications. Moreover, you can also use waste plastics, rubber, oil sludge, medical waste as raw material, which are all quite cheap in the market. With high value and stable prices in the market, these end-products will surely get your cost of raw materials back soon and bring great benefits for you.

2.Machine cost

About the machine cost, firstly I want to introduce that the 2 types plastic to oil machine we have. One is batch type plastic to oil machine, the capacity is from 100kg per batch to 10ton per batch. The other one is fully automatic continuous plastic to oil machine, the capacity is from 10T/D to 100T/D. About the plastic to oil machine cost, it's different depends on different configurations. 3.Installation cost

3.Installation cost

In order to save the installation cost for customers, we have developed a new design of the machine to make it into frameset. This way, the machine no need much installation works in customer 's factory.

4. Land & construction cost

Firstly, land cost is mainly decided by the installation size of the machine. And the plastic to oil machine no need much construction cost, only need to build a roof to keep the machine out from wind and rain is ok. 5.Operation cost

5.Operation cost

About the operation cost of the machine, it's mainly about the power consumption and worker's salary.

Related recommendation:

tire pyrolysis

continuous pyrolysis plant

pyrolysis plant south africa

plastic pyrolysis plant cost

Inquiry:

Click here to get the latest price

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@wastetireoil.com

http://www.wastetireoil.com