What is Tyres Pyrolysis?

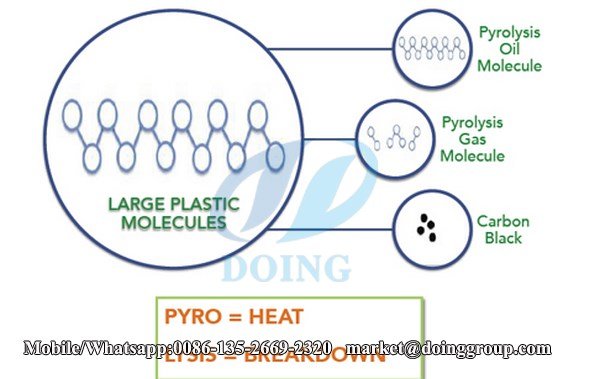

Pyrolysis is a thermochemical decomposition of organic material at elevated temperatures in the absence of oxygen (or any halogen). It involves the simultaneous change of chemical composition and physical phase, and is irreversible. The word is coined from the Greek-derived elements pyro “fire” and lysis “separating”.

Pyrolysis is a thermochemical decomposition of organic material at elevated temperatures in the absence of oxygen (or any halogen). It involves the simultaneous change of chemical composition and physical phase, and is irreversible. The word is coined from the Greek-derived elements pyro “fire” and lysis “separating”.

The pyrolysis method for recycling used tyre is a technique which heats whole or shredded tires in a reactor vessel containing an oxygen free atmosphere and a heat source. In the reactor the rubber is softened after which the rubber polymers continuously break down into smaller molecules. These smaller molecules eventually vaporize and exit from the reactor. These vapors can be burned directly to produce power or condensed into an oily type liquid, generally used as a fuel. Some molecules are too small to condense. They remain as a gas which can be burned as fuel. The minerals that were part of the tire, about 40% by weight, are removed as a solid. When performed well a tire pyrolysis process is a very clean operation and has nearly no emissions or waste.

The pyrolysis method for recycling used tyre is a technique which heats whole or shredded tires in a reactor vessel containing an oxygen free atmosphere and a heat source. In the reactor the rubber is softened after which the rubber polymers continuously break down into smaller molecules. These smaller molecules eventually vaporize and exit from the reactor. These vapors can be burned directly to produce power or condensed into an oily type liquid, generally used as a fuel. Some molecules are too small to condense. They remain as a gas which can be burned as fuel. The minerals that were part of the tire, about 40% by weight, are removed as a solid. When performed well a tire pyrolysis process is a very clean operation and has nearly no emissions or waste.

Pyrolysis of scrap tyre can separate solids in the tire, such as steel wire and carbon black, from volatile liquid and gaseous compounds that can be used as fuel. Although the pyrolysis of waste tires has been widely developed throughout the world, there are legislative, economic, and marketing obstacles to widespread adoption.

Pyrolysis of scrap tyre can separate solids in the tire, such as steel wire and carbon black, from volatile liquid and gaseous compounds that can be used as fuel. Although the pyrolysis of waste tires has been widely developed throughout the world, there are legislative, economic, and marketing obstacles to widespread adoption.

Related equipments:

continuous plastic pyrolysis plant

continuous plastic pyrolysis plant

continuous waste tyre pyrolysis plant

continuous waste plastic pyrolysis plant

waste oil distillation machine

waste engine oil recycling to diesel machine

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:market@doinggroup.com